ZEISS introduces new AM parameter qualification solution

September 13, 2021

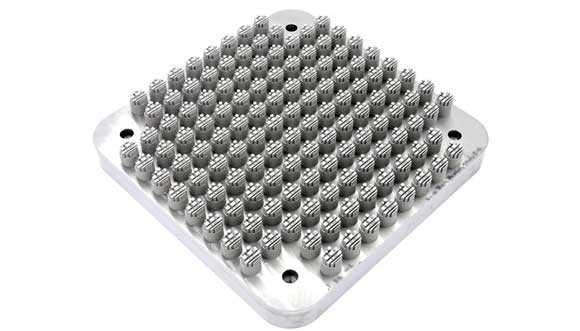

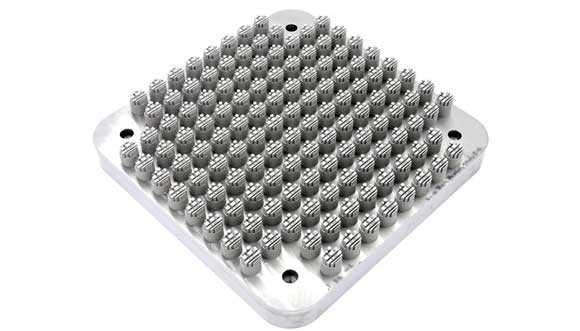

ZEISS Group, headquartered in Oberkochen, Germany, has introduced ParAM (Parameter for Additive Manufacturing), a new Additive Manufacturing parameter qualification solution at RAPID + TCT 2021, which is currently taking place in Chicago, Illinois, USA, from September 13–15.

ZEISS ParAM, using its unique test design and evaluation workflow, enables it to be used as a versatile solution for multiple applications. Examples include evaluating parameters to build defect-free parts with a change in powder quality or a degree of recycling, developing build parameters for thicker powder layers, qualification of a build envelope, evaluating or compensating for a laser performance in multi-laser systems, and creating a parameter to produce deformation-free parts. One, or a combination, of these parameter optimisations is said to help reduce the build failure rate and make AM processes reliable, while reducing the cost per part.

ZEISS and Oak Ridge National Laboratory (ORNL), Oak Ridge Tennessee, USA, have been collaborating at the Manufacturing Demonstration Facility – a Department of Energy national user facility at ORNL – on the development of a novel, fully automated solution to comprehensively evaluate a set of parameters in less than twelve hours.

“Our goal is for the user to start with a design of experiments, print coupons and evaluate best print parameters from the design of experiments plan in the same day, so they are ready to print parts the next morning,” stated Pradeep Bhattad, Product Manager for ZEISS ParAM.

Ryan Dehoff, section head for secure and digital manufacturing at ORNL, commented, “Currently only a handful of alloys are qualified for printing and the majority of these are used in conventional manufacturing. However, there is tremendous benefit in developing and qualifying novel alloys specifically designed for Additive Manufacturing. The current challenge is the qualification process, and technologies that can accelerate the development of new materials are critical.”