Volkswagen pick-up fitted with additively manufactured front-end structure

September 1, 2017

The front-end structure of this VW Caddy has been completely redesigned using Additive Manufactring

Altair, APWORKS, csi entwicklungstechnik, EOS GmbH, GERG and Heraeus have used the front-end structure of a classic VW Caddy pick-up to demonstrate the full potential of industrial Additive Manufacturing (AM) within the automotive industry.

The final structure is very light, stable, and, at the same time, features a high degree of functional integration. In this joint development project known as 3i-PRINT, the companies involved covered every development step of the process, from design, simulation, optimisation and manufacturing to post-production of the part. From conceptual design to final vehicle, the project was completed in only nine months.

The value of Additive Manufacturing for the automotive industry

Driving innovation and impacting decisive development processes, metal AM will play an integral role in large-scale manufacturing over the next few years. The technology is already being deployed in a wide range of industries and the constant evolution of production and design techniques using AM will make the technology even more cost-effective and efficient in the future. As such, the use of industrial metal AM will continue to grow, particularly in the automotive industry.

The true value proposition of Additive Manufacturing in automotive engineering can only be realised with considerations extending far beyond structural mechanics and lightweight construction. This functional integration – implementing as many technical features as possible with as few components as possible with the resulting added value – is an additional key advantage that makes the use of AM lucrative for the automotive industry. With the Caddy concept, the 3i-PRINT project aims to demonstrate future technological possibilities.

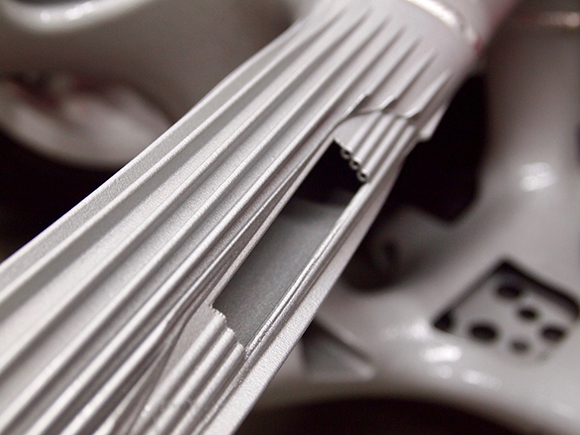

Detail showing the complexity of the AM structure

Organic design for load-bearing structures

In view of the growing trend towards electrification in the automotive sector, heat management as well as the reduction of design space and overall weight were crucial factors when designing the front-end section. Moreover, structural requirements relating to vehicle safety, performance and comfort needed to be addressed.

Accordingly, parts of the additively manufactured front are load-bearing structures that include details for both active and passive cooling – for example with a channelled airflow to cool batteries and brake systems. In addition, functions linked to heat management, passive safety and fluids storage have been integrated in the organic, load-driven design of the front-end module.

Combined expertise along the process chain

With these goals in mind, the experts at csi entwicklungstechnik began designing, developing and building the front-end structure. The company develops high-quality modules for vehicle bodies, interiors and exteriors for both manufacturers and suppliers in the automotive sector.

GERG is a leading supplier of innovative solutions in the area of prototyping and small-scale series for the automotive and aerospace industries. In this project GERG was responsible for connecting the additively manufactured components and the creation of the final frame.

With its focus on the development and broad application of simulation technology to synthesise and optimise designs and processes, Altair’s software solutions were used to design, optimise, simulate and develop the structure.

After the successful simulation and design of the concept, APWORKS took care of the final dimensioning of the components for AM. APWORKS contributed its knowledge of file preparation and handled the actual Additive Manufacturing of the structural elements. As a subsidiary of Airbus, the company is very familiar with state-of-the-art manufacturing processes and enables various industries to implement best practice concepts from the aerospace sector.

When producing the front end, APWORKS relied on a system developed by EOS, a leading technology supplier in the field of the industrial AM of both metals and polymers. Metal powder specialist Heraeus supplied and qualified the high-strength aluminium alloy Scalmalloy®, developed by APWORKS, to manufacture the components. APWORKS provided support for the manufacturing process by developing the ideal parameter sets for the EOS M 400 system. Thanks to the combined use of AM and this innovative material, the project successfully demonstrates the possibilities of functional integration that traditional manufacturing methods are unable to offer.

The 3i-PRINT project, a forum for innovative prototype concepts

Initiated by csi entwicklungstechnik, the 3i-PRINT project acts as an agile engineering platform for research and development enabling innovative prototype concepts. The idea is based on the use of new development tools and methods, including industrial AM. The project’s goal is to demonstrate and fully exploit the potential of state-of-the-art manufacturing methods. The 3i-PRINT project is an open platform for collaboration that quickly enables the implementation of new ideas.

Stefan Herrmann, responsible for light weight design within the body in white team at csi, stated, “We are proud to present the Caddy with an exemplary new additively manufactured front-end structure. The new structure and the contrast between old and new impressively demonstrates the potential that 3D printing and functional integration offer, particularly for the automotive industry.”

Herrmann continued, “I would also like to emphasise the agile, time-efficient route from the initial idea to the fully converted vehicle, which was completed within only nine months. Each of the participating companies is a leader in its field. The outstanding collaboration and combined expertise has made the 3i-PRINT project a resounding success.”