Texture Jet offers sustainable surface post-processing

March 9, 2023

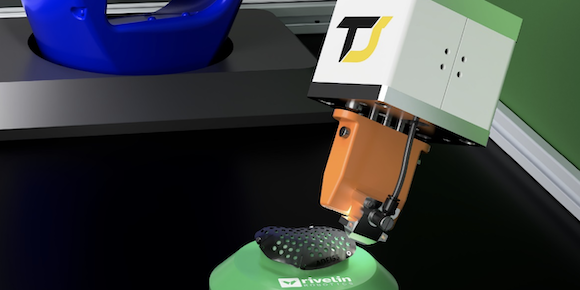

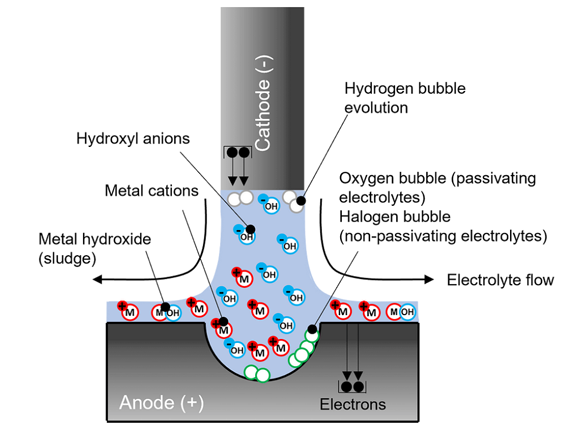

Texture Jet Ltd, based in Nottingham, UK, is using its patented electrochemical jet machining (EJM) technology, a highly localised variant of electrochemical machining (ECM), to post process metal additively manufactured parts.

Using its EJM process, Texture Jet offers the ability to control and manipulate surface textures and finishes on metal components, enabling a wide variety of surface finishes from rough to smooth and matte to glossy.

By eliminating the need for traditional finishing methods, Texture Jet’s technology is said to significantly reduce the time and cost required to produce high-quality metal components. This optimisation of the surface is also said to improve the components’ mechanical properties, reduce friction & wear, and improve their overall performance & durability.

“By leveraging advanced surface engineering techniques,” stated Jonathon Mitchell-Smith, Texture Jet CEO & co-Founder, “Texture Jet’s technology can provide a symbiotic relationship with AM build processes that enable and enhance lowering production costs and increasing sustainability within the AM process chain, providing a much greater value proposition.”

Texture Jet’s post-processing can also help make AM more sustainable and environmentally friendly by minimising waste and reducing the need for harmful chemicals and abrasive materials.

The technology has been engineered as a plug-and-play system that can be integrated into a wide variety of delivery systems depending on the application. The Gen Trio system is a standalone system that can be used for small, high-precision AM parts. The STAT system can be integrated into robotic systems or used in a bespoke system to suit the surface finish requirements of the part.

Download Metal AM magazine