MT Ortho uses GE Additive Arcam EBM technology to customise prostheses

June 24, 2020

GE Additive Arcam EBM’s Electron Beam Powder Bed Fusion technology (PBF-EB) technology is being used by Italian medical supplier MT Ortho to produce customised prostheses for cranioplasty and bone cancer patients. MT Ortho has a reported twenty years of experience in the Italian clinical-hospital market for standardised prostheses, and began to implement Additive Manufacturing in 2014 when it invested in two of GE Additive Arcam EBM’s machines.

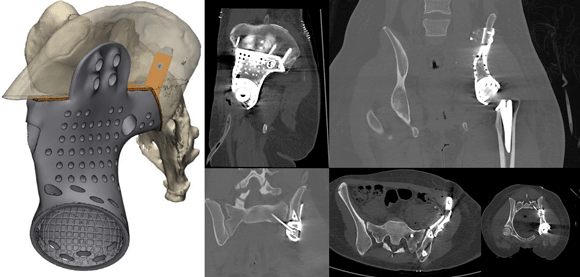

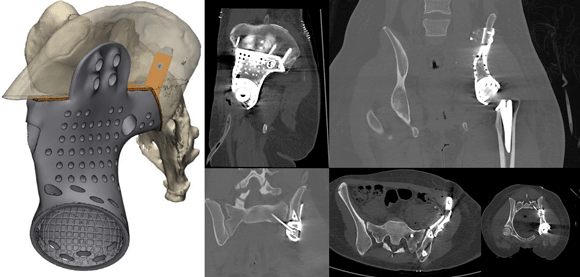

The MT Ortho team initially focused on the production of customised prostheses for neurosurgical applications (custom cranioplasty) and oncological orthopaedics (mega-prostheses reconstruction). By combining diagnostic imaging technologies with the design freedom of Additive Manufacturing, the company states that it has opened up new opportunities in prosthetics, enabling customised patient devices and improving the effectiveness of diagnosis, planning, surgery and clinical outcomes.

Customised prostheses are medical devices exclusively designed for an individual patient, for their particular pathology, and then manufactured according to their specific diagnostic images. This type of implant is mainly used when bone geometry is not within the dimensional range of standard implants, when there are special requirements due to disease, or simply when a tailor-made solution enables a better clinical result.

Leveraging its experience distributing a wide range of medical-surgical devices to hospitals, public and private healthcare facilities, and its more-recently gained experience in AM, MT Ortho explains that it has continued to develop solutions for orthopaedic surgery, oncological orthopaedics, neurosurgery and maxillofacial surgery – all sectors whose needs often cannot be met by conventional manufacturing methods.

This has led to the development of a new line of customised cranioplasty prostheses, now in use throughout Europe. The use of AM in cranioplasty is said to make the prosthetics process easier and much more precise. In addition, the characteristics of the technology make it possible to achieve an optimal structure for osseointegration, and by virtue of the speed and precision of the technology, it is also easier to carry out the so-called demolition/reconstruction operations for cranioplasty in a single step.

These interventions are based on a completely different surgical strategy that allows the most precise planning of the intervention, for which MT Ortho states that it provides not only the prosthesis but also the cutting templates – following the precise mapping of the intervention area by a CT scan.

In surgery, the removal of the area affected by disease, and the insertion of the cranial prosthesis, can take place simultaneously to the surgery to place the new prosthetic, reducing post-operative hospitalisation and recovery time and the risk of infection. This is particularly important for interventions in sensitive areas such as the ocular orbit or the craniomaxillofacial region.

The company notes that in the treatment of bone cancer, Additive Manufacturing can offer significant advantages, especially when combined with digital image processing and artificial intelligence technologies, making it possible to prepare a 3D intervention plan through the fusion of several CT images.

MT Ortho now specialises in the development of AM cancer prosthetics for bone sarcomas or chondrosarcomas. By using AM, the company states it is possible to perfectly reconstruct the bone anatomy of patients after demolition surgery performed for the removal of a tumour.

This area of expertise has reportedly been particularly successful thanks to a collaboration with the Department of Oncological Orthopedics at the National Cancer Institute Regina Elena of Rome (IRE) in Rome, where MT Ortho is achieving encouraging intervention results.

Simone Di Bella, who was first employed as a graduate engineer specialising in Additive Manufacturing by MT Ortho in 2014 when it was initially adopting AM, commented, “Our goal was to become not only a distributor, but also a manufacturer of medical devices. And our vision was to achieve this by creating new, innovative devices with unique features that were only possible by using Additive Manufacturing and were more compatible with the human bone than metals on the market at the time.”