FreeFORM expands technology offering with addition of MIM services

November 24, 2021

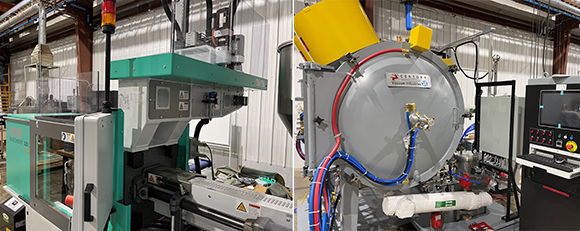

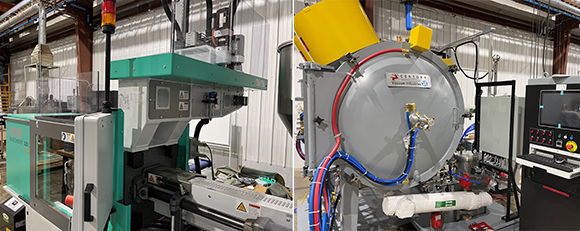

FreeFORM Technologies, St Marys, Pennsylvania, USA, reports that it has expanded its technology solutions offering to provide Metal Injection Moulding (MIM) services, along with its metal Binder Jetting (BJT) capacity, thanks to the recent acquisition of two fully automated Arburg Allrounder 320 C injection moulding machines and a vacuum debinding and sintering furnace for MIM and sinter-based AM from Centorr Vacuum Industries.

Founded in 2020, FreeFORM has developed a strong presence in the metal BJT service bureau landscape. The company has worked to educate customers of the benefits of Binder Jetting, especially during the current supply chain crisis. FreeFORM explains that the current market has led to nearly all industries looking for new or secondary suppliers for their products, and the impacts of the COVID-19 pandemic has revitalised a drive for companies to explore tool-less technologies such as metal Additive Manufacturing.

In the company’s first twelve months of business, it delivered over 45,000 additively manufactured parts to more than twenty-five customers worldwide. “AM 2.0 is alive and well,” stated Nathan Higgins, president of FreeFORM Technologies. “We have seen a great increase in customer and prospect RFQ activity for new and conversion products. FreeFORM strives to operate as a function of the customers engineering teams, solving their most complex problems. Along with our customers, equipment manufacturers, and powder suppliers, we have helped customers launch products in several new binder jetted materials in 25% of the typical time for traditional manufacturing.”

“Volume is a still a recurring question from our customers when it comes to Additive Manufacturing and some still prefer to manufacture high volumes of parts with traditional technologies like Metal Injection Moulding [MIM],” Higgins continued. “Our goal at FreeFORM is to continue to build on the acceleration of the AM 2.0 movement, but as a customer first business the message was loud and clear, we needed to offer additional technology.”

FreeFORM finished the installation of the injection moulding machines, along with additional sintering capacity, in Q3 2021. With this new capacity and additional technology, the company anticipates that it can continue to serve its customers from ideation through production with or without tooling.

Chris Aiello, vice president of Business Development, FreFORM Technologies, added, “When we were presented with the opportunity to acquire these assets and the transfer tooling that came along with them, it was a no brainer for us. MIM is a natural fit to complement our existing capacity, plus people know our team as ‘MIM guys’ from our past roles, so it feels right to add this offering. Over the past twelve months, we have had countless requests from customers to offer MIM. We had explored some alternatives, but to Nate’s point, the writing was on the wall – we needed to offer this to our customers.”

For more background on FreeFORM Technologies, read ‘FreeFORM Technologies: Leveraging MIM expertise to drive application development in metal Binder Jetting’ the lead article in the June 2021 issue of PIM International.