Desktop Metal and Uniformity Labs partner to deliver Binder Jetting powders

December 7, 2021

Desktop Metal, Burlington, Massachusetts, USA, and Uniformity Labs, Fremont, California, have announced a partnership to qualify and deliver ultra-low porosity Binder Jetting (BJT) powders that exhibit high sintered part density and mechanical properties when processed on Desktop Metal’s BJT machines. This follows the companies’ previous collaboration in March, which led to the development of a new aluminium powder for BJT.

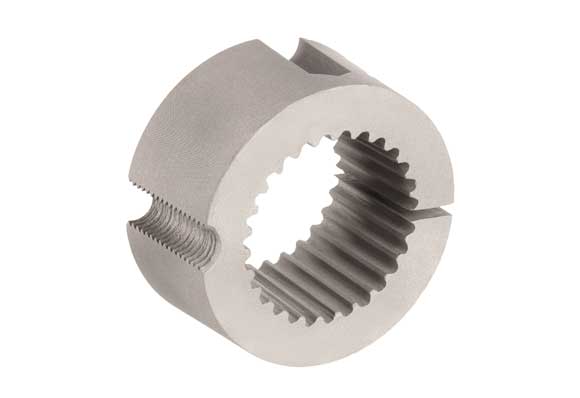

Uniformity Labs has developed patented materials technology that enables the production of powders with tap densities of up to 85%, that sinter to full density and are more flowable than powders of comparable size. These materials are said to be unlike any other in their ability to repeatably spread uniformly across the build plate at the highest relative density, thereby delivering high sintered part density with low part shrink.

The goal of the partnership is to leverage Desktop Metal’s high-speed Binder Jetting systems and processes with Uniformity Labs’ metal powder processing capabilities to create industry-leading, integrated solutions that make it easier for businesses to adopt BJT to produce end-use metal parts at scale.

The collaboration is focused on qualifying optimised BJT powders exclusively for Desktop Metal solutions, including the Production System™, Shop System™, and ExOne build platforms. Together, the companies are studying powder and binder interactions and will release build profiles with fully characterised mechanical properties for various materials, including stainless steels, nickel-base superalloys, and reactive metals such as aluminium.

“We are excited to unveil this strategic partnership with Uniformity Labs, which is pioneering materials solutions that will advance the AM industry,” stated Ric Fulop, founder and CEO of Desktop Metal. “Binder Jetting powders processed with Uniformity Labs technology enable unmatched mechanical properties and can further improve the economics of printing. We look forward to collaborating with the Uniformity Labs team to optimise Binder Jetting powders exclusively for Desktop Metal’s AM 2.0 solutions and provide our customers with integrated offerings including hardware, software, and materials that enable robust adoption of AM for mass production.”

In order to accelerate materials qualification and enhance collaboration between the companies, Uniformity Labs has installed several Desktop Metal systems at its Fremont facilities, including a Shop System and a Production System P-1. The partnership has already resulted in the qualification of several high-performance, engineered powders for Desktop Metal’s Shop System, which are commercially available to customers exclusively through Desktop Metal as part of its turnkey Shop System solution.

Uniformity Labs topologically engineered powders for Desktop Metal’s Production System and ExOne platforms will be available directly through Uniformity Labs. Additionally, the companies plan to continue to work together to qualify the aluminium 6061 powder on Desktop Metal’s Production System platform and scale production for commercial release.

Adam Hopkins, founder and CEO of Uniformity Labs, added, “This partnership strengthens our ongoing collaboration with Desktop Metal to provide incredible value for its customers looking to adopt next-generation AM solutions. We are thrilled to continue our work with Desktop Metal to qualify our high-performance, engineered powders that deliver superior mechanical properties, surface finish, and part reliability.”