Creaform introduces new suite of automated dimensional quality control solutions

September 28, 2020

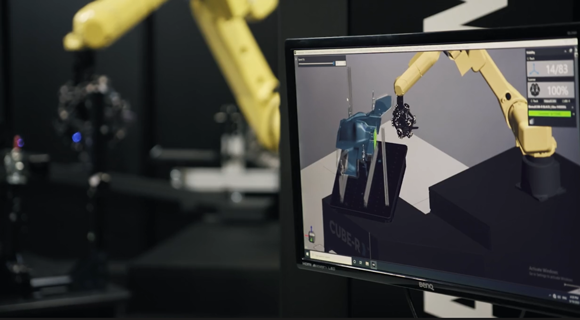

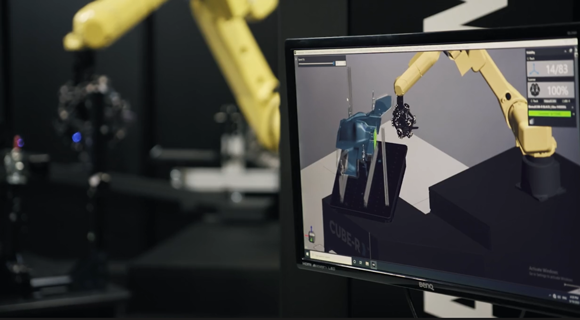

Creaform, a 3D measurement solutions provider based in Lévis, Québec, Canada, has announced the latest release in its R-SeriesTM lineup, including its new MetraSCAN-R BLACK|EliteTM as well as the addition of four different models in its CUBE-R 3D scanning measuring machine. Creaform also launched its VXscan-RTM digital twin environment software module, which completes the company’s turnkey automated quality control solution suite.

Designed for automated quality control applications, the R-Series 3D scanning solutions are said to enable manufacturing companies to increase productivity by measuring more dimensions on more parts, without compromising on accuracy. The MetraSCAN 3D-R is a robot-mounted optical CMM scanner that can be seamlessly integrated into automated quality control processes for at-line inspection in mass production.

The CUBE-R is said to leverage the power of the MetraSCAN 3D-R in a high-productivity industrial measuring cell designed to be integrated into factories for at-line inspections. Compared to traditional CMMs, the CUBE-R is reportedly faster, providing improved productivity and efficiency.

“Manufacturers need to achieve fast, accurate and repeatable output – now more than ever before. With Creaform’s automated quality control solutions, manufacturers can increase their productivity,” stated Jérôme-Alexandre Lavoie, Product Manager at Creaform.

“By detecting and addressing quality issues faster based on statistical analyses, corrective measures can be more proactively implemented to mitigate total quality costs (TQC) and unprofitable recalls,” added Lavoie.