3DEO reports 600% revenue growth in 2019

May 11, 2020

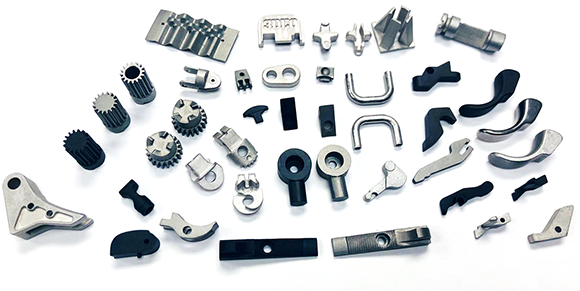

3DEO, Inc., a metal Additive Manufacturing technology company based in Los Angeles, California, USA, has announced a 600% growth in revenues for 2019 over 2018. The company also reported a 394% increase in the number of additively manufactured parts shipped in 2019, with approximately 25% of parts being for aerospace, 35% for medical and 40% for defence applications.

The number of employees at 3DEO was also reported to have increased to sixty, up 172% compared to the twenty-two employees in 2018. AM machines used at 3DEO for part production were said to have increased by 566%. 3DEO’s printers are built with proprietary technology, specialised for serial production and manufactured in the USA.

“We are very proud of the growth that was accomplished over the last year,” stated Matt Sand, President of 3DEO. “It is clear that 2020 will be another record-setting year for 3DEO as our pace of adoption across all industries is accelerating. More than a metal 3D printing company, 3DEO is a solutions provider helping our customers tackle their most challenging manufacturing problems.”

The company started as an Additive Manufacturing business with its patented metal AM technology, Intelligent Layering®, at its core. However, in order to compete in high-volume traditional manufacturing, the company stated it evolved into a vertically integrated, next generation factory. This new business model allows manufacturers to gain the cost savings, design freedom, and manufacturing flexibility needed to compete – without having to incur millions of dollars for a metal AM machine and the supporting infrastructure.

Amidst a downcycle in manufacturing jobs in America, 3DEO reports that its new solution-focused business model is creating new jobs. High-tech production workers work with robotics and automation and its most noteworthy employee increase was in the R&D department. With over twenty-five engineers, 3DEO states it is continuously improving core processes and technology up and down the production line.

Sand added, “What’s more, almost every customer we are working with is using metal 3D printing in production for the first time. We are in the trenches with our customers, and our growth curve is a testament to the demand for these solutions. In the end, our mission is to do for manufacturing what Amazon’s AWS did for the internet by offering low-cost access to flexible, scalable, and world-class manufacturing infrastructure.”

Matt Petros, 3DEO’s CEO, commented, “We’re doing things in manufacturing that previously couldn’t be done. And we’re doing it by leveraging several enabling technologies that are converging right now in manufacturing – in a way that finally allows metal 3D printing to shift the serial production paradigm.”