BASF invests $25 million in Materialise as companies seek to optimise AM materials and software

July 19, 2018

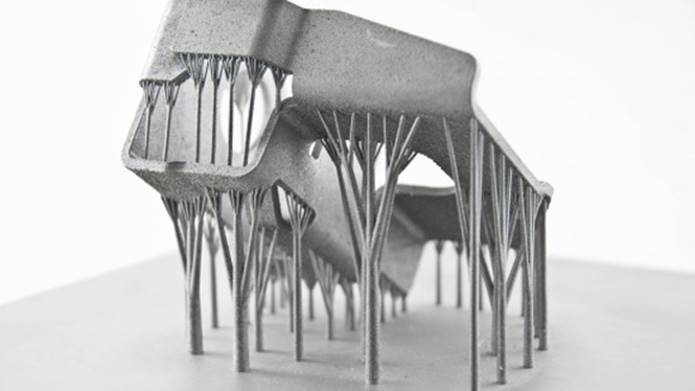

A part demonstrating support structures automatically generated by Materialise’s Magics software (Courtesy Materialise)

BASF, Ludwigshafen, Germany, has invested $25 million in Materialise, Leuven, Belgium, and announced further cooperation between the two companies to improve materials and software for various Additive Manufacturing technologies. The companies are focusing on applications in the automotive and aviation industries as well as in the consumer goods sector. The agreement will reportedly allow for systematic, wider scale testing and further optimisation by BASF of its materials on the machines and within the infrastructure of Materialise.

“Our two companies’ business areas complement each other very well and our cooperation will put us in an even better position to find and develop new business opportunities,” stated Volker Hammes, Managing Director of BASF 3D Printing Solutions GmbH. “With its 3D printer facilities in Leuven and innovative software solutions, Materialise has an outstanding infrastructure. Together, we can exploit our strengths even better to advance the 3D printing sector through the development of new products and technologies together with our partners and our customers.”

“To increase the adoption of 3D printing as a complementary manufacturing technology for final products, our industrial customers increasingly demand more control, more choice and ultimately lower cost,” added Fried Vancraen, Materialise CEO. “We are confident that this collaboration with a leading manufacturer of materials will help to accelerate the adoption of 3D printing in existing vertical markets and create significant business opportunities in new markets.”