Adira presents AddCreator machine for large-scale metal Additive Manufacturing

November 24, 2017

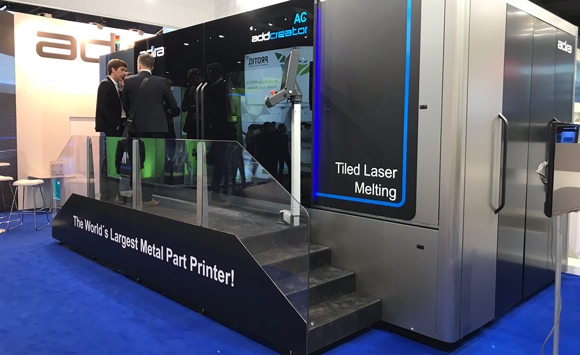

The AddCreator was displayed at the recent formnext exhibition in Frankfurt, Germany

Portuguese-based manufacturing company Adira has released a new large-scale metal Additive Manufacturing system, the AddCreator (AC). Displayed at the recent formnext exhibition in Frankfurt, Germany, the AC claims to offer the largest working volume of any metal powder Additive Manufacturing machine.

The system uses Adira’s Tiled Laser Melting (TLM) process, which divides the work area of a build into smaller segments or ‘tiles’ to be processed sequentially. This is said to enable more efficient and flexible production of very large components which it may not be possible to produce using traditional AM.

Using TLM, it is also possible to produce parts larger than the AC’s build chamber volume. By making use of a moveable chamber, atmospheric conditions can be maintained solely in the working area, allowing as-needed expansion of the build area without compromising system functionality.

The AC system incorporates a number of useful features aimed at making metal Additive Manufacturing more accessible to the market, such as an automated powder cycle for easier cleaning and sieving of used powder, quicker supply and storage.

The machine also offers full production chain integration and an optimised infrastructure for the removal of parts, comprising multiple access areas and the capacity for cooperative interaction with an external robotic handling system. Additionally, integrated laser and process-related equipment is reported to offer end-users to a cleaner and more efficient work environment, free of unnecessary peripherals.

Adira was founded over sixty years ago and formerly specialised in the production of its own widely-used press brakes, shears and laser cutting systems for sheet metal processing. Tthe development of TLM and release of the AC mark the company’s first entry into Additive Manufacturing and Industry 4.0.